Superbolt’s technology eliminates unsafe, inaccurate and time-consuming bolting methods.

Phone: 262-798-0535

Providing Industrial Productivity Solutions for Assembly, Custom Lifting, Material Removal, and MRO

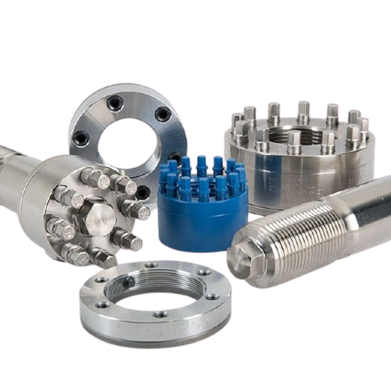

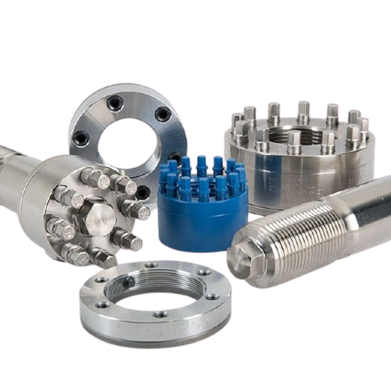

AEHH is proud to be your midwestern based distribution partner for all four divisions of the Nord-Lock Group. The Superbolt, Boltight and Nord-Lock divisions provide the technology you need to solve your complex bolting application, whatever your industry, while the Expander division eliminates lug wear of pivot pins in many industries as well. List below are the four divisions of the Nord-Lock Group, select one of the thumbnails to learn more about that product.

Superbolt’s technology eliminates unsafe, inaccurate and time-consuming bolting methods.

The Expander System offers a simple and cost-effective solution to lug wear.

Boltight’s hydraulic tensioning solutions offer fast, safe and accurate tensioning of single or multiple studs simultaneously.

Nord-Lock’s wedge-locking technology secures bolted joints exposed to severe vibration and high dynamic loads.

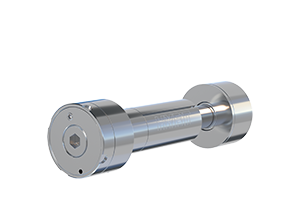

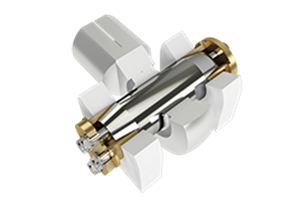

When securing nuts and bolts with large thread diameters, using turn torque methods are often unsafe, time consuming and unreliable. Superbolt makes this task simple, safe and affordable by mechanically tensioning nuts and bolts. Tensioning is widely accepted as the most accurate way to control preload offering a 10% tolerance, where turn torque methods are a 30% tolerance at best. Superbolt was the world’s first to revolutionize nuts and bolts with multi-jackbolt tensioning technology. Since then, their technology has been proven in tens of thousands of successful installations and they continue to develop a multitude of solutions to solve the next generation of bolting challenges.

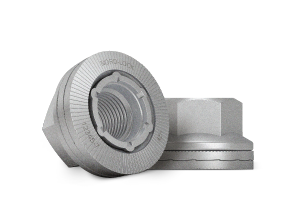

Superbolt multi-jackbolt tensioners (MJTs) take the high preload requirements in large diameter bolting and break it down into manageable torques using the jack bolts threaded through the nut body. These jack bolts stretch the stud evenly by reacting against a special washer designed as part of the assembly. The result is an accurate preload achieved with the use of only hand tools, even with large thread diameters at high loads.

Superbolt multi-jackbolt tensioners (MJTs) take the high preload requirements in large diameter bolting and break it down into manageable torques using the jack bolts threaded through the nut body. These jack bolts stretch the stud evenly by reacting against a special washer designed as part of the assembly. The result is an accurate preload achieved with the use of only hand tools, even with large thread diameters at high loads.

Click here to learn more about how Superbolt can benefit your process on our productivity solutions page.

Click here to learn more about how manufacturers are using Superbolt OEM.

Watch the below video to learn more about how MJT's work!

Superbolt expansion bolts are truly fitted into the hole due to the radial expansion of the conical bore sleeve.

By design, accurate radial force combined with the known axial clamping load, provides total protection against coupling slippage and thus prevents bolt and hole damage during subsequent removals.

The expansion bolts can be retrofitted to replace traditional interference or force fitted bolts, reliably and cost-effectively.

Watch the below video to learn more about how expansion bolts work!

Superbolt has expanded into many new product lines over the years. Shown below are the different categories of products that AEHH can offer you from Superbolt.

Superbolt Tensioners

Replace or retrofit existing bolts to safely achieve accurate preloads.

Superbolt Flexnuts

Help relieve stress concentrations and increase fatigue life of bolts and studs.

Superbolt Customized Solutions

Custom designed solutions for your unique application requirements.

Superbolt HyFit

Hydraulic retrofit and raplcement to coupling bolts.

Superbolt EzFit

For rotating couplings that require bolts to transfer bolts to shear.

Superbolt Tool

The fastest and simplest way to tighten Superbolt MJT's.

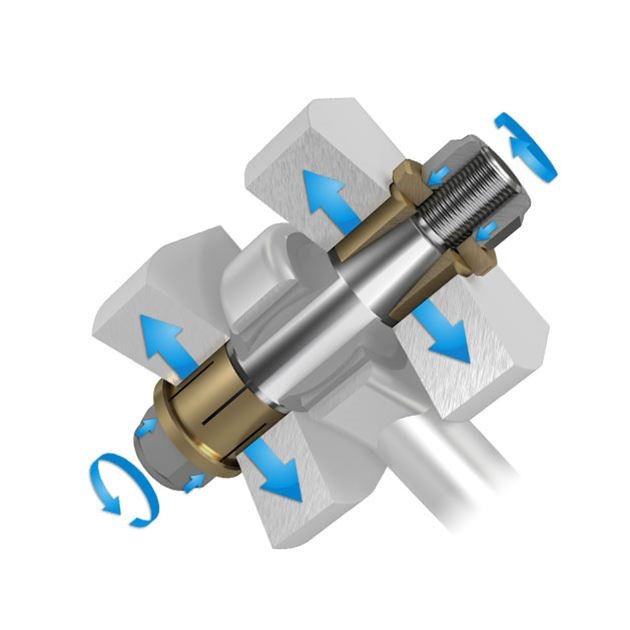

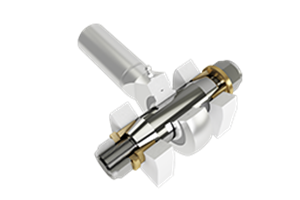

For years, line boring has been a necessary expense for many companies that utilize heavy machinery with pivot pins. This process is not only costly but time consuming as well. Expander System pivot pin technology provides a permanent solution to lug wear and eliminates these costs and down time for your machinery. The system can be installed directly into the lugs of a new machine or be used as a spare part for repairs, eliminating the need for expensive welding and line boring.

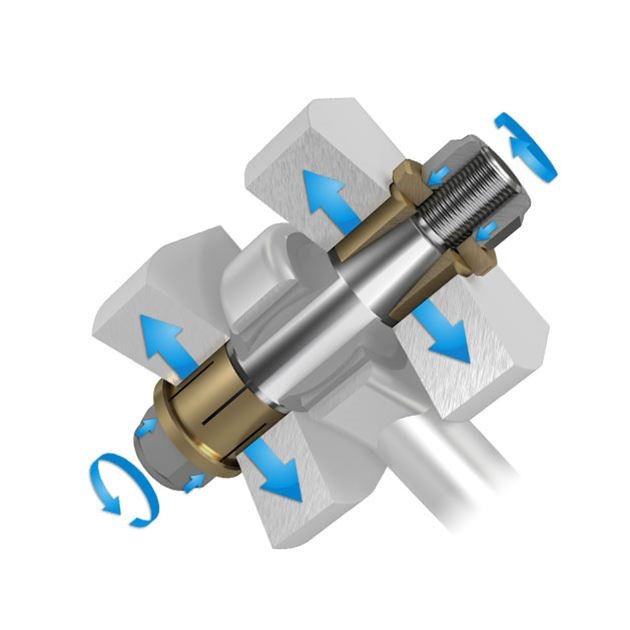

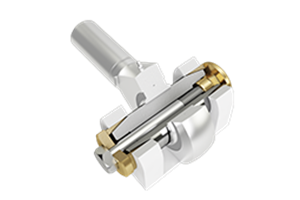

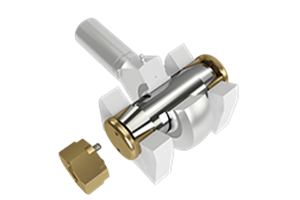

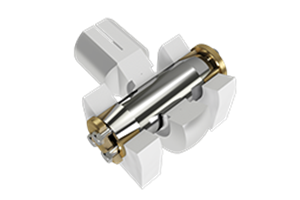

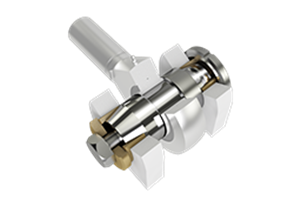

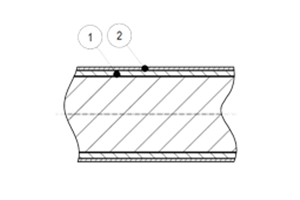

Expander System uses a bushing design that loosely fits into the lug and has the ability to expand up to 0.800”. This is achieved by applying torque to the nut on the outside of the assembly, forcing the tapered bushing to expand against the reverse taper of the pin, shown left. This results in an accurate load that is distributed over the entire bottom half of the lug. Instead of the pin deforming the lug, you simply replace bushings as they wear. This product is backed by a 10 year / 10,000 hour warranty.

Expander System uses a bushing design that loosely fits into the lug and has the ability to expand up to 0.800”. This is achieved by applying torque to the nut on the outside of the assembly, forcing the tapered bushing to expand against the reverse taper of the pin, shown left. This results in an accurate load that is distributed over the entire bottom half of the lug. Instead of the pin deforming the lug, you simply replace bushings as they wear. This product is backed by a 10 year / 10,000 hour warranty.

Check out the video below to learn more about Expander's Pivot Pin Technology!

The Expander line has many different standard sizes and materials, as well as the ability to custom manufacture pins to your requirements. Shown below are some of the most common products Expander offers.

Contact us today to learn how Expander can help increase the life of your machinery.

Nut and Washer System

Designed for applications with no obstacles around the pivot joint.

Bolt and Washer System

Designed for applications with no obstacles and pivot joint diameters that are > 38mm.

Bolt and Recessed Washer System

Designed for applications with moving obstacles and a large lug diameter.

Through Bolt System

Designed for applications with space constraints on one side.

Flat Head System

Designed for applications with moving obstacles and narrow lug width.

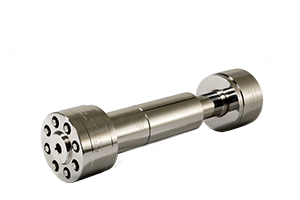

Multi-Bolt System

Designed for heavy duty applications and large diameters.

Stepped Pin System

Designed for hitch pin applications with axial locking.

Offshore System

Specially designed for Offshore Applications

Customized Systems

Custom designed solutions for your unique application requirements.

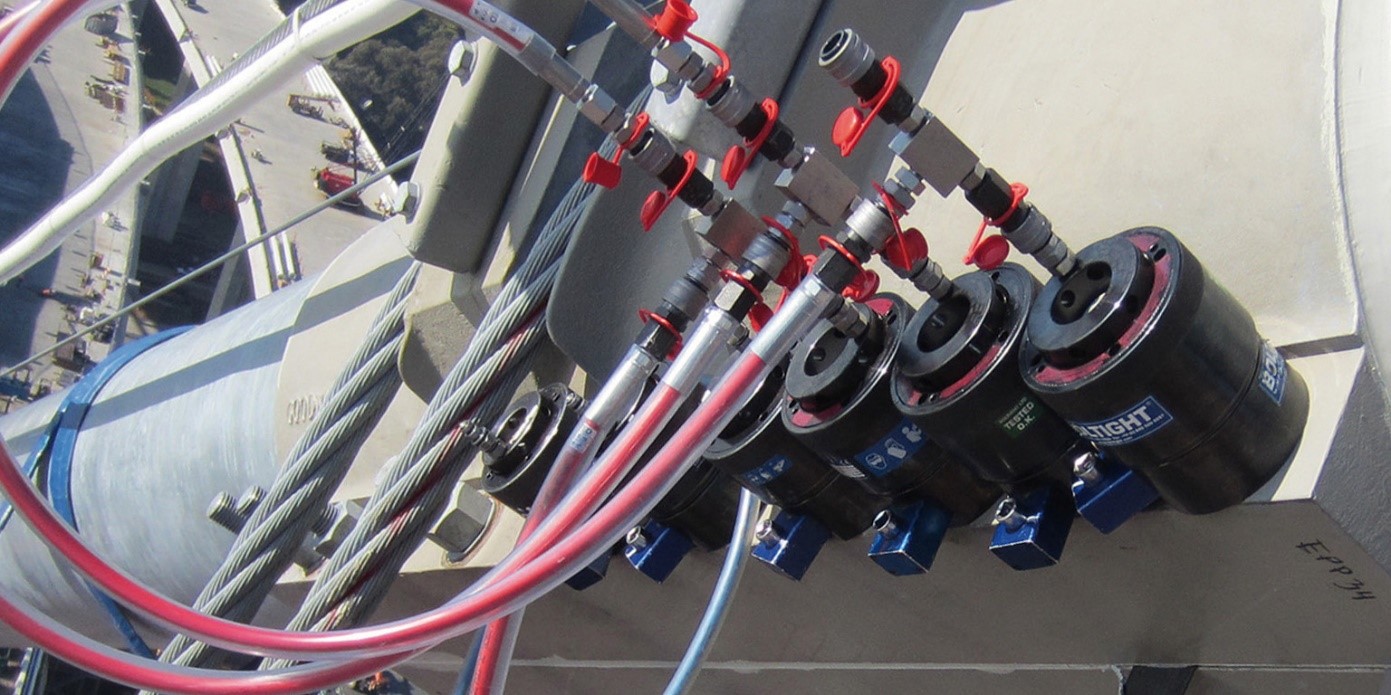

Large threaded fasteners are often difficult to secure with turn torque methods. As previously discussed, Superbolt provides a great solution with their mechanical tensioners. Boltight provides another great solution and has been at the forefront of hydraulic bolt tensioning for over a decade. Their tensioning tools provide fast, accurate and safe solutions to tension and loosen single or multiple studs simultaneously.

Boltight stud tensioning solutions make it possible to tighten and loosen studs one at a time or simultaneously using high-pressure hydraulics. Bolt tensioners which are shown in the pictures below, stretch the stud before the nut is wound down under zero friction, ensuring extreme accuracy, speed, uniformity and safety of any bolt tightening situation. Tensioning methods are rated to a 10% tolerance of the targeted preload, where the most accurate turn torque tool can only offer a 30% tolerance in a perfect world. This makes tensioning a much more effective way to secure fasteners.

Watch the below video to learn more about how Boltight's Stud Tensioner works!

Boltight’s hydraulic nuts provide the convenience of incorporating the hydraulic tensioner into the threaded nut. This flexible solution stays with the equipment, making it less work to install and disassemble the nuts. Hydraulic nuts offer great time savings for applications where the nuts are continually assembled and disassembled for access or repair like press columns.

Watch the below video to learn more about how Boltight's hydraulic nut works!

Boltight offers many variations of their products to best suit your needs. For more information on Boltight products, contact us today.

Standard Bolt Tensioners

Designed to fit all standard oil & gas flanges. Easy and ready to install.

Sub Sea Tensioners

Nickel plated tensioners, designed for high initial bolt stress.

Typhoon Tensioners

Designed to fit tight access areas, suitable for wind turbine applications.

Boltight's Echometer Series

A compact and portable system that accurately measures bolt elongation with ultrasonic tooling.

TSR+ Tensioners

The fastest auto-relief system on the market, designed to ensure fast and safe operations.

Xtra Range Tensioners

Designed for high loads and tight areas. Fits Norsok compact oil & gas flanges.

Foundation Tensioners

For wind bases and foundation bolts, this tensioner works for most common thread forms.

Hydraulic Nuts

Permanent replacement for where nuts are required.

Closure System, Rotor Tools & Casing Tool

Application specific tooling for the Power Generation Industry.

Accessories

Accessories for your application including Pumps, Hoses, Connectors and Fittings.

Engine Tool Sets

For the installation and maintenance of gas and diesel engines.

Custom Tensioner Solutions

Custom designed bolting solutons for your unique application requirements.

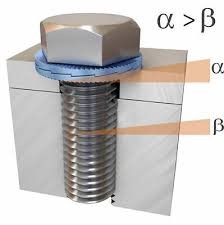

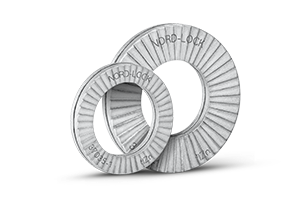

Bolts exposed to high vibration have been an ongoing struggle to keep secure in a variety of applications. The challenge is that often, these fasteners need to be removed and reused which creates a problem for products like ny-lock washer. Adhesives have their place but is normally a one-time solution, that often requires the improper use of high strength bonds. This can result in difficultly removing bolts and may even damage to your product. Nord-Lock created the original wedge-locking technology that secures bolted joints and was designed to be reused, even when exposed to severe vibration and dynamic loads. It is impossible for our products to loosen unintentionally due to the wedge created underneath the bolt head and nut.

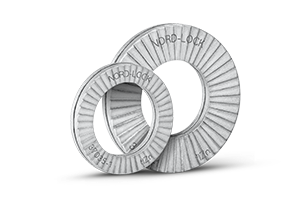

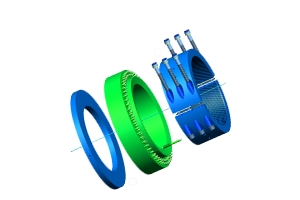

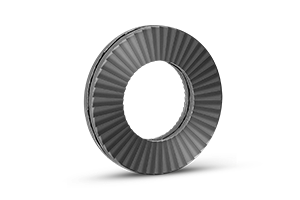

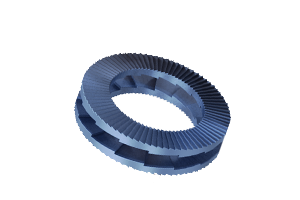

Nord-Lock wedge-locking technology secures bolted joints with tension instead of friction. The system is composed of a pair of lock washers with cams on one side and radial teeth on the other.

Nord-Lock wedge-locking technology secures bolted joints with tension instead of friction. The system is composed of a pair of lock washers with cams on one side and radial teeth on the other.

Nord-Lock wedge-locking products secure the fastener in a joint which cannot be loosened even when subjected to extreme vibration or dynamic loads. The Nord-Lock range includes steel construction washers, wheel nuts, combi bolt washers and custom solutions.

How the Nord Lock Washer Works!

Nord-Lock Washers have many categories shown below. Contact us to discuss how wedge-locking technology may benefit your application.

Original Washer Series

Wedge-locking security for bolted joints subjected to high vibration and dynamic loads.

X Washer Series

Maximum security for bolted joints exposed to spontanious loosening and slackening.

Steel Construction Series

Used in construction applications, including HV and HR sets.

Nord-Lock Wheel Nuts

Eliminate wheel loosening on heavy vehicles operating in extreme conditions.

Combi Bolt Washers

Additional security for applications through permanent attachment to bolts. (SEMS)

Customized Solutions

Custom designed solutions for your application requirements.