Plant Maintenance Solutions

Keeping your plant up and running is a time sensitive task that can impact your bottom line. This is especially true when ongoing challenges are left unresolved. In situations like this, AEHH is here to help with innovative solutions you may not have considered. Shown below are (5) solution categories that will save your company money with no additional sacrifice in time. In fact, most categories will actually reduce necessary maintenance time. Click on any category to learn more.

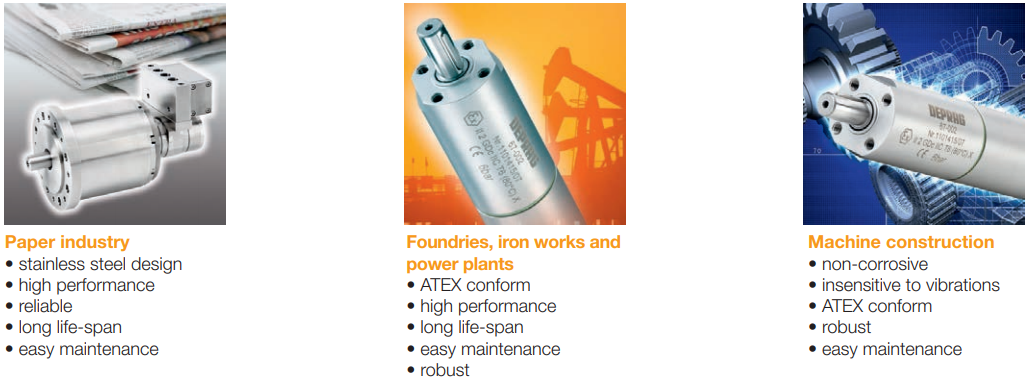

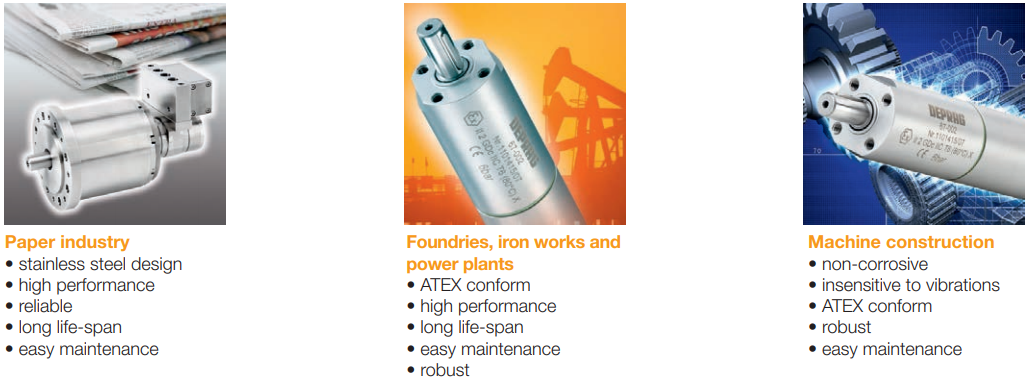

Deprag Air Motors

With nearly a century of experience, German based Deprag offers you an enormous range of air motors that can be precisely matched to your application requirements. With standard, turbine, corrosion proof, food grade, clean room and other specialty motors to choose from, you can be assured Deprag has the right solution for you!

Hydraulic Tensioning Solutions

Boltight solutions make it possible, both in plant and in field, to achieve accurate preload when tightening and loosening single or multiple bolts simultaneously. Bolt tensioners stretch the stud under zero friction rather than turning them down to a torque requirement. This ensures extreme accuracy, speed, uniformity, and safety of any bolt tightening situation.

Superbolt Tensioners

Superbolt has made bolting simple with the use their multi-jackbolt tensioning technology. This system allows for high preloads to be achieved with the use of simple hand tools. Proven in tens of thousands of successful installations, Superbolt is continually developing new solutions to solve the next generation of bolting challenges. If you have applications with thread diameters ¾” or larger, this is a must view!

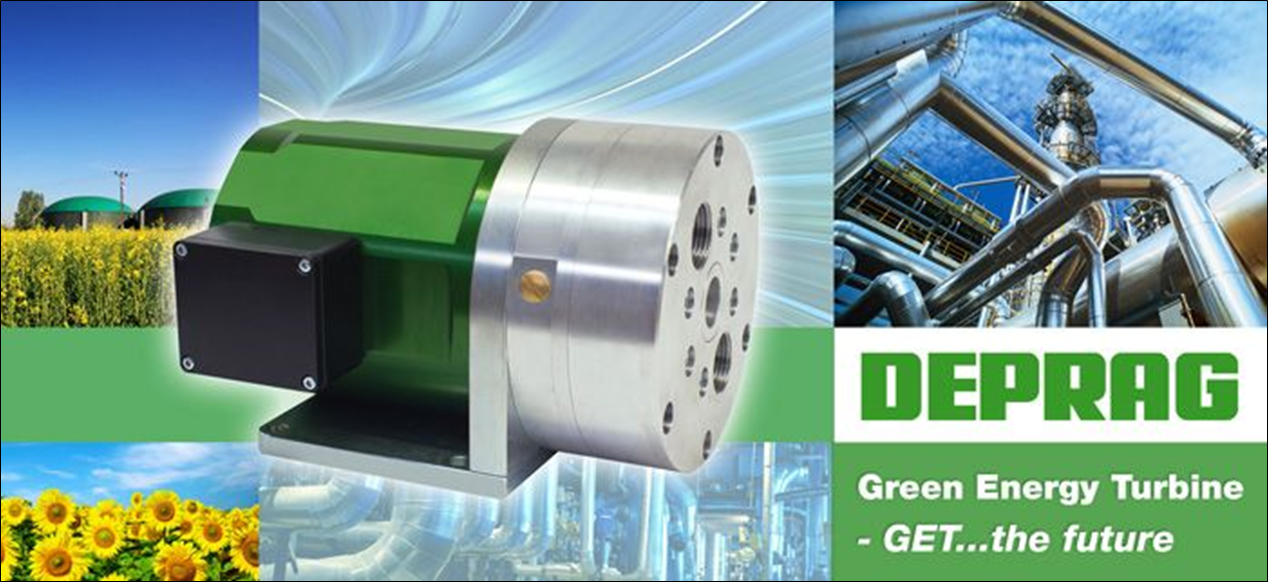

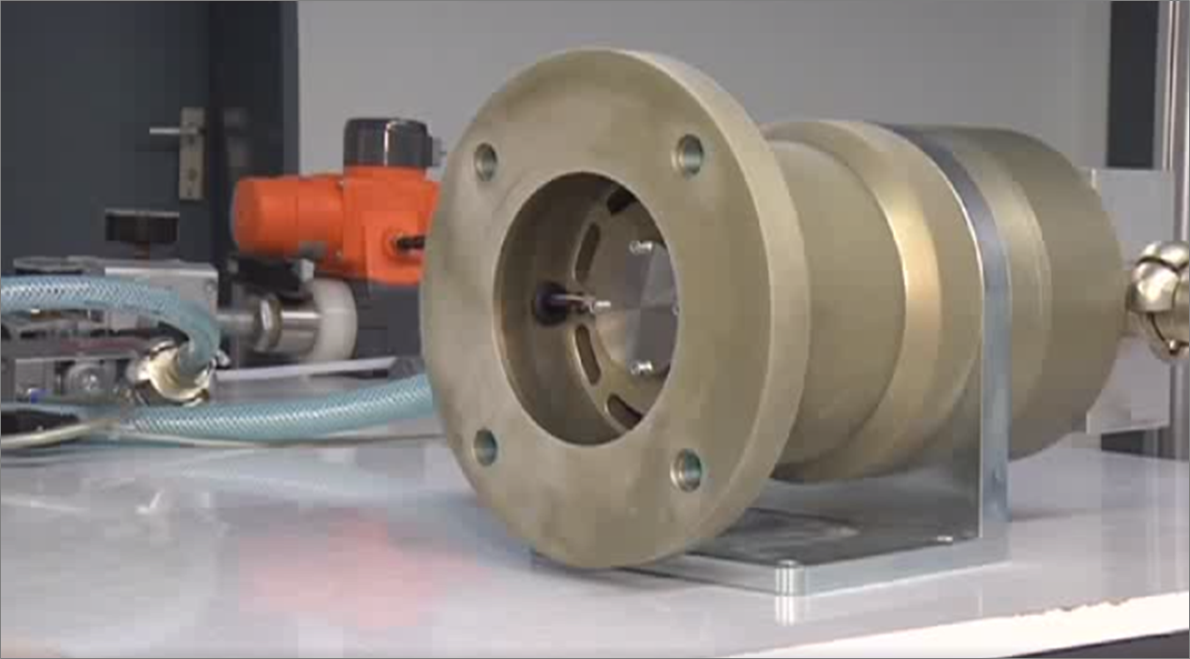

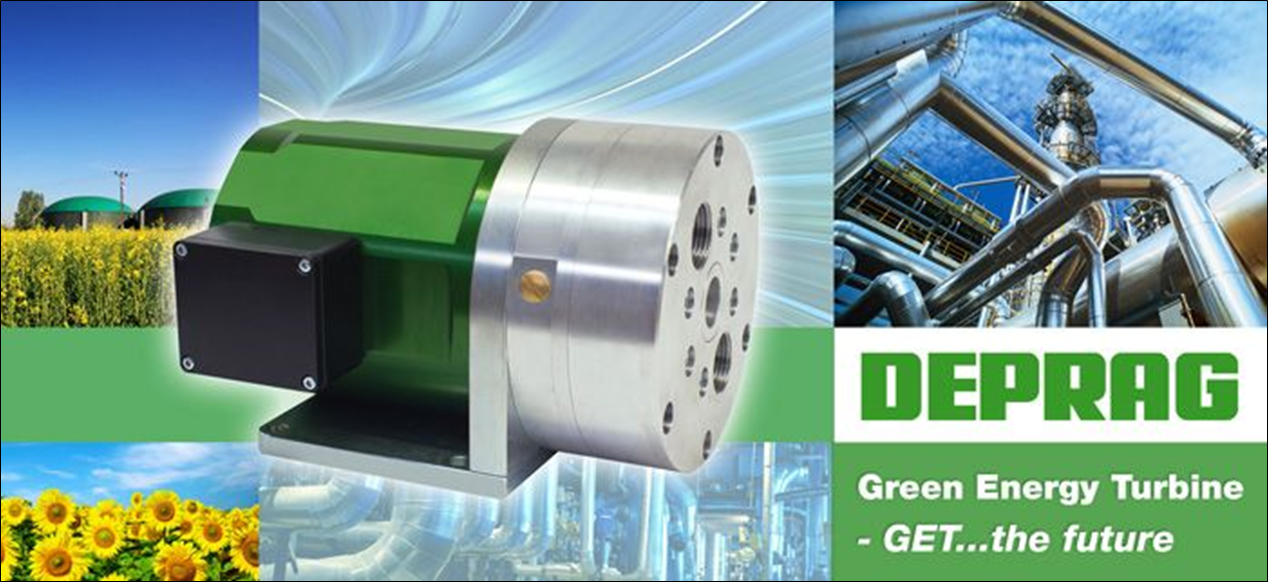

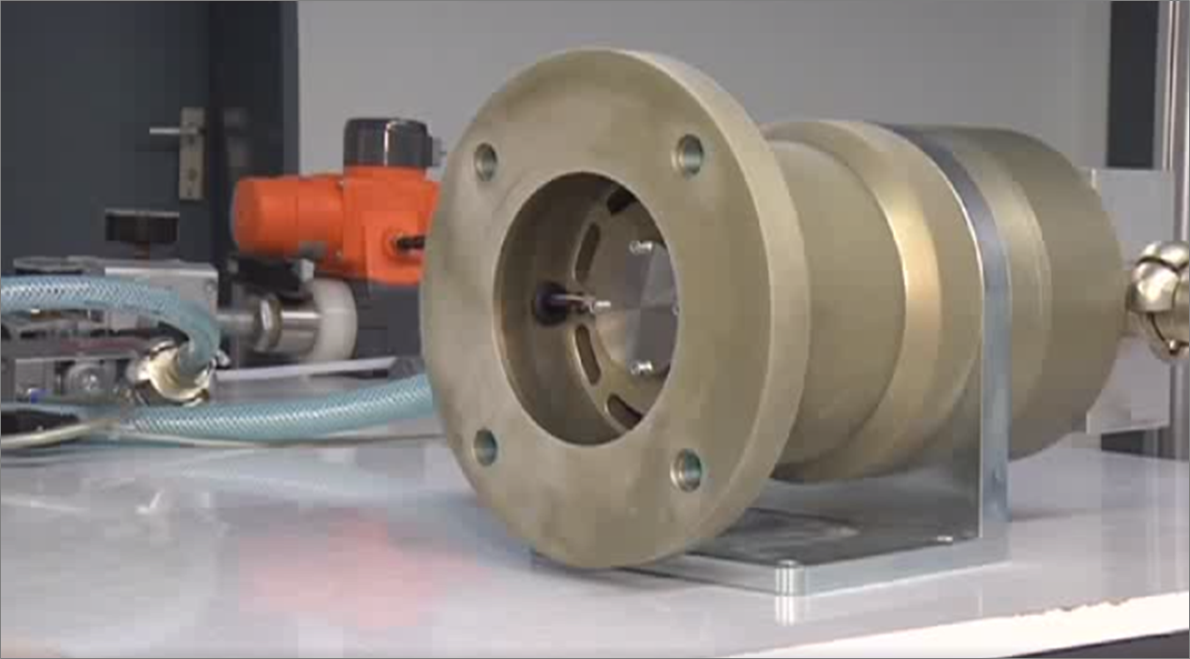

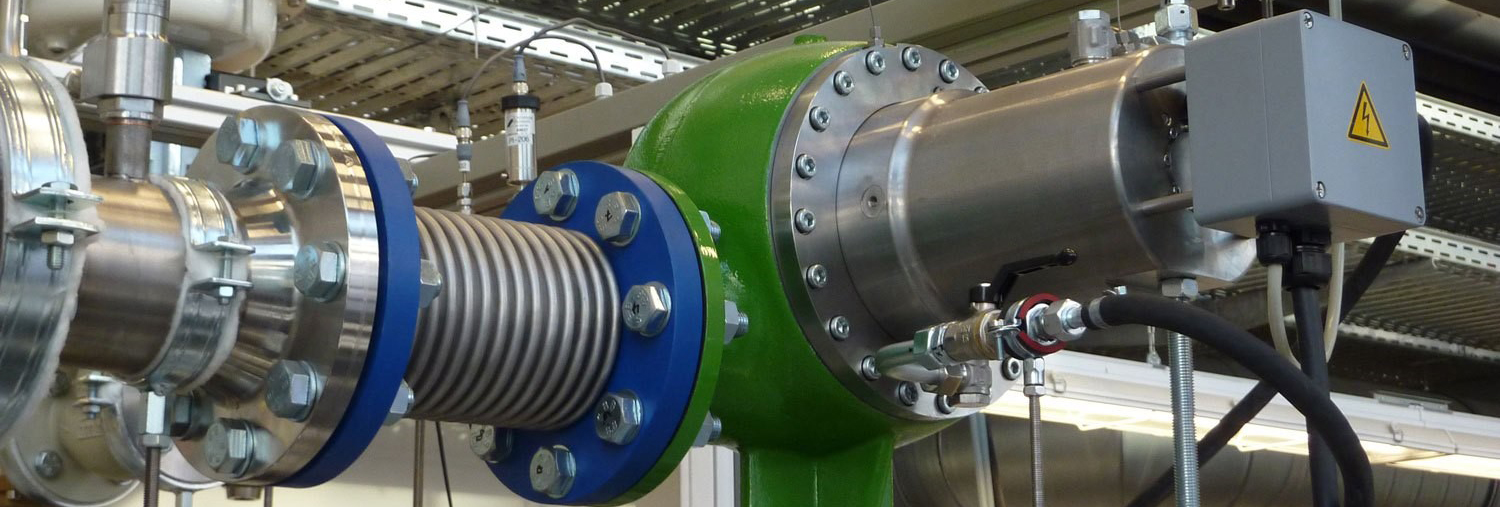

GET Energy Recovery

In specific applications were thermal energy is lost to the atmosphere, Deprag’s GET technology can capture this wasted energy and convert it into electricity. Significant energy cost savings are possible, even at lower kW levels.

Exhausted Air Recycling System

Learn how E.A.R.S. can save you up to 40% on air compressor energy consumption, by capturing exhausted air from your pneumatic tools and returning that air, supercharged, back to your compressor!

DEPRAG AIR MOTORS

Sourcing reliable air motors can be a challenge for manufacturers. With tighter station layouts small profile motors, with large power output, have become a necessity for today’s manufacturing plants. Deprag offers the solution with their turbine series air motors. These compact design solutions offer big performance from a small package by harnessing the same technology found in jet engine turbines. Deprag offers safe and robust drive systems in applications where overload-safe and powerful drive is required. This is especially true in areas where conventional drive technology cannot continue to rotate.

Deprag excels in applications where air motors must be oil-free, sealed, and insensitive to cleaning solvent. This is important in applications like the food industry and medical applications when motors must be sterilizable. The ATEX-compliant motor series offers protection for the total system – including air motor, brake and gearing, these robust motors are ready to be used in explosion hazardous environments.

AEHH will help you select the most economical and the safest drive solution that best fits your application, we have you covered whether the solution is an air motor from Deprag’s catalog program or if it is a complex customized system.

Features of Deprag Air Motors

Benefits to Your Process vs Conventional Drive Technology

- Reduced Downtime

- Increased Durability

- Reduced Lead Time for Service

Contact us today to learn more about what Deprag air motor best fits your application.

Mechanical Tensioning Solutions by SUPERBOLT

Securing fasteners with high preloads is now simple, safe and affordable with Superbolt. Superbolt products achieve clamp load by applying a small torque input into each jackbolt that reacts on a washer, as shown below. The result is a large output that is easily achieved with common hand wrenches. Many manufactures with presses use Superbolt products to maintain accurate preloads on their press columns, tie rods, die cushions and more! When the energy sector requires a reliable method to secure turbine couplings, foundation bolts, boiler feed heaters, pumps, valves and other critical connections, Superbolt delivers the solution that will reduce down time, improve quality control and increase worker safety.

For example, a lubricated Grade 8 Bolt with 1.500" thread would require 1,581 ft-lbs. of torque to reach load.

For example, a lubricated Grade 8 Bolt with 1.500" thread would require 1,581 ft-lbs. of torque to reach load.

A Superbolt product at same spec only require 33 ft lbs. of torque to each jack bolt – easily achievable with hand tools.

Features of Superbolt Products

- No special tooling required

- One-man operation

- Input torque is safely achieved using hand tools

- Nuts and bolts can be tensioned to within 10% of the desired preload (Turn Torque Methods average 30% or greater)

Benefits to Your Process vs Conventional Turn Torque Methods

- Reduced Time to Install and Remove

- Improved Quality Control

- Reduce Risk of Injury

Click here to learn more about Superbolt on the Nord-Lock Group Tab or contact us to discuss your bolting challenge.

GET Energy Recovery

Features of the GET

- Converts wasted energy into cost savings

- Highest degree of efficiency

- Small, compact and rugged

- Maintenance-free

- Low investment

Benefits to Your Process

- Converts recovered waste energy into income.

- Significantly reduces your energy costs.

For more information on Deprag's GET, contact us today.

https://deprag.com/fileadmin/bilder_content/Green_Energy/Videos/Get_Deprag_english_640x480.mp4

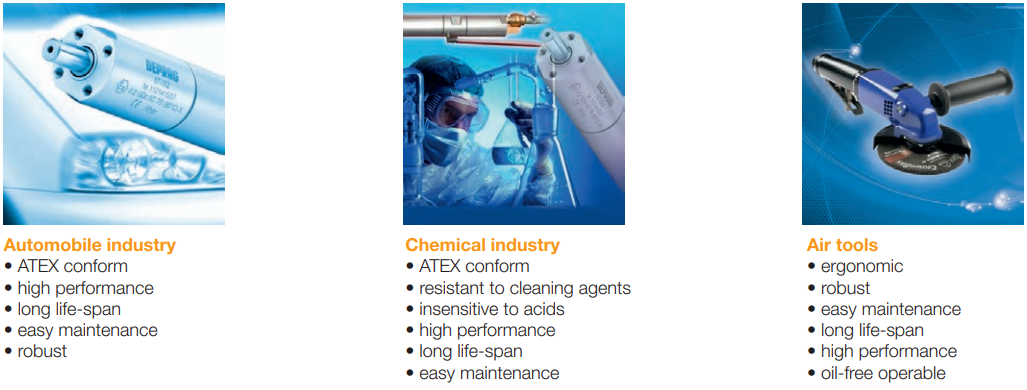

Exhausted Air Recovery Systems

Air tools are a vital part of your plant’s operation; however, it is very costly to generate compressed air to run them. Exhausted Air Recycling Systems (E.A.R.S) has a solution that will allow you to use your current style tools and put money back into your pocket. By capturing the exhausted air and returning it to the air compressor through a modified intake manifold, your compressor will run less and reduce any issues keeping up with the demands of your shop. Many companies experience growth which is a good thing, but when you run out of air compressor capacity, it can mean investing huge capitol in a new compressor system. E.A.R.S allows you to stay in your current set up long, without sacrificing performance.

Features of E.A.R.S

- Reduced run time of air compressor up to 40% translates into direct energy savings.

- Air Compressor takes less time to recover

- Recycled air is clean and dry, keeping your tools running longer.

- Exhausted Air is captured, eliminating debris blowing around

- Overall noise dB reduced up to 30%

- Captured exhaust eliminates pollution emissions caused by oiled air lines.

Benefits to Your Process

- Reduced Energy Consumption

- Reduced Risk of Injury

- Reduced Tool Repair Cost

Contact us today to learn more about E.A.R.S or to schedule a demonstration of our system.

For example, a lubricated Grade 8 Bolt with 1.500" thread would require 1,581 ft-lbs. of torque to reach load.

For example, a lubricated Grade 8 Bolt with 1.500" thread would require 1,581 ft-lbs. of torque to reach load.