Torque Control Solutions

Tools that control and document torque and angle.

Phone: 262-798-0535

Providing Industrial Productivity Solutions for Assembly, Custom Lifting, Material Removal, and MRO

When your application is critical, tooling with process control capabilities ensure the job is done correctly the first time. At AEHH, we understand how to implement these technologies into your process. Click on one of the below categories to see solutions we can provide, based on your application.

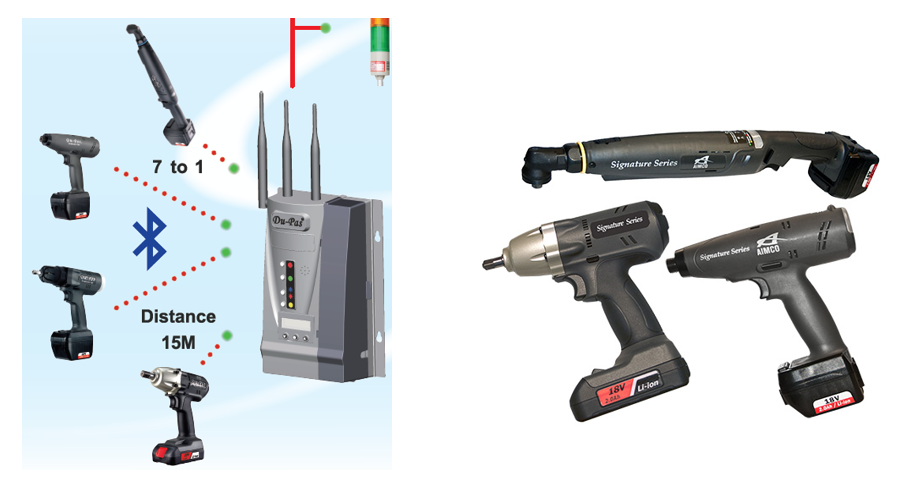

During assembly, and when torque fastening applications are critical, the use of advanced technology to control your process will increase your consistency and improve overall product quality. AEHH offers many torque control solutions at different levels of sophistication and capability. Transducer and angle-controlled tools are popular for critical joints, and can give you the flexibility to handle any challenge including, different joints and multiple toque and angle steps. While These tools communicate with controllers by way of customized settings to ensure every piece of hardware is fastened correctly. Additionally, these controllers are equipped with 24V I/O and different protocols for line indexing – with Open Protocol, Ethernet IP, Device Net and MES being the most commonly used. Many of our products also communicate with Pin Point.

Looking for solutions to increase productivity in your assembly process? Click Productivity Solutions to see solutions AEHH has introduced into the market.

Precision Torque Control & Angle Control

Batch Counting & Cross Thread / Rehit Detection

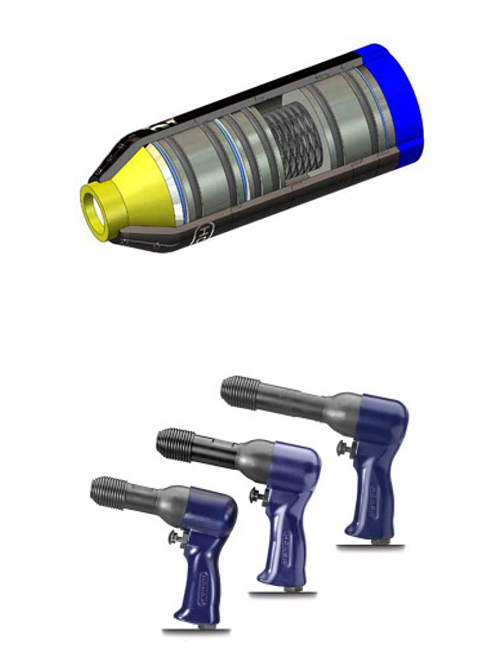

While riveting has been a standard form of fastening for over 60 years, today, the process is often viewed as providing minimal quality control from the tooling side. As a result, high levels of rework are frequently seen. AEHH offers solutions for both buck and pop riveting that’ll improve your quality through refined tool control, by counting rivets and auditing a pass or fail.

Interested in increasing your productivity in riveting applications? Contact us to learn more how these products could benefit your process.

Buck Riveting

Blind / Pop Riveting

Lock Bolts

Rivet Nuts

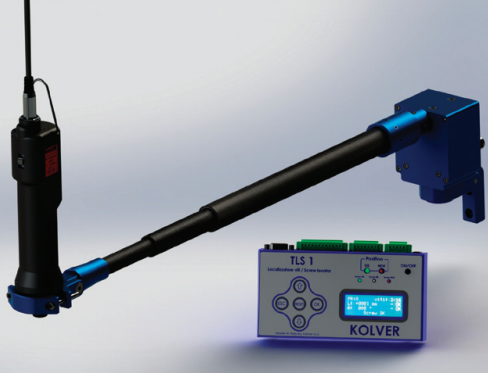

Smart arms have become an important part of the assembly process. Smart arms will disable an assembly tool unless it is in, precisely, the correct position. This ensures that torque sequences are properly followed - and that parts, like pins, are driven to the correct depth. When paired with a product such as AIMCO’s Gen IV Controller, you achieve a smart arm system with step by step work instructions shown directly on the controller screen.

Contact us today and let's discuss how your productivity can be increased through the use of Smart Arm technology.

Light Assembly Smart Arms

Heavy Assembly Smart Arms

Controller Step by Step Work Instructions