Deprag Smart Grinder (DIQ)

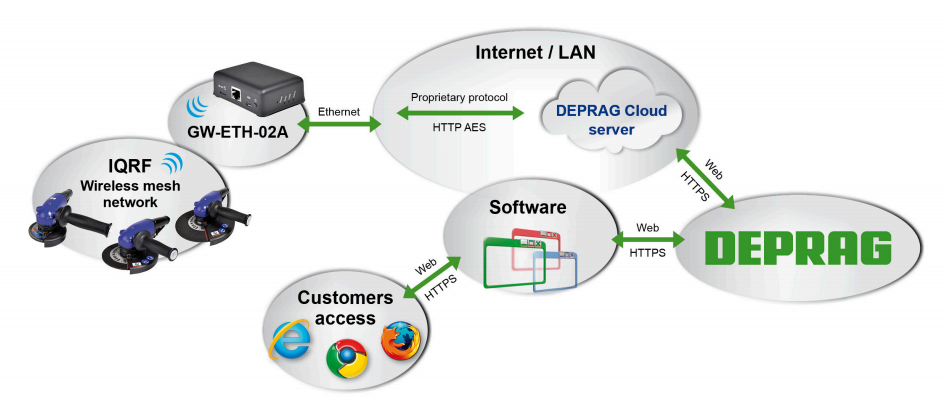

A revolutionary technology that allows wireless monitoring of the tools performance. Alerting you who the tool is overloaded and allowing you to know what tool really is best for the job.

Phone: 262-798-0535

Providing Industrial Productivity Solutions for Assembly, Custom Lifting, Material Removal, and MRO

Keeping your grinding room running efficiently is critical your process. AEHH has to solutions to help keep parts moving and your operators feeling fresh at the end of a long workday. Browse the below categories to learn more about what solutions may be of benefit to your application.

Deprag Smart Grinder (DIQ)

A revolutionary technology that allows wireless monitoring of the tools performance. Alerting you who the tool is overloaded and allowing you to know what tool really is best for the job.

Low Vibration Percussive Tools & Grinders

Learn why many foundry’s and die cast manufactures are looking to Honsa Ergonomic Technologies to provide ergonomic relief through low vibration air tools.

Turbine Grinders

Learn how Deprag turbine grinders reduce the time and effort to grind your parts.

Flexible Shaft Grinders

Suhner Flexible Shaft Electric Grinders provide an unrivaled power to weight ratio with optimal rpm control.

Diamond Grinding Wheels

Diamond plated grinding wheels have proven to greatly reduce cost when used on gray and ductile iron. Learn more about how specialty tooling can maximize the life of these super abrasives.

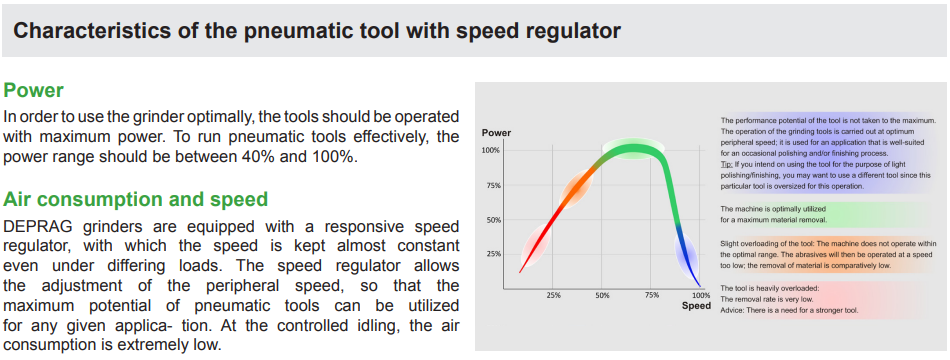

Pneumatic grinders have been a stability in material removal and surface preparation for over a century, but the technology has been standing still since that time. Small advances, such as turbine motors and ergonomic designs has improved tool performance and worker safety, but this industry has been lacking in the area of new age technology. The DiQ Series is the first truly revolutionary offering in this field by giving you the ability to live monitor the workload on each grinder through a wireless mesh system. This shows when tools are being used optimally and when they are becoming overloaded or underutilized.

Click here to learn more about Deprag's DiQ Series!

Operators who use percussive tools or rotary tools with repetition often experience the loss of feeling in their hands and fingers. The problem lies within the air tools that are required for their job. Although providing a great advantage, these tools fail to provide protection from harmful vibration that may lead to serious injuries through accumulation. Shipyards, foundries, steel fabricators and many other industries rely on Honsa tools because of their ergonomic advantage. Honsa’s patented polymer, tunes the harmonic frequency into non harmful waves. The result is that your workers no longer experience tingling or number hands and fingers after using their tools, allowing them to perform at a higher level.

For more information on Honsa's low vibration air tools or to schedule a demonstration, please contact us today.

Air tools have used the same rotory vane design for years, resulting in a plateau of performance offered like power to weight ratio. Deprag offers a complete line of turbine grinders to supercharge your grinding process. By using turbine motors, Deprag has been able to significantly increase horsepower and reduce the weight by close to 30%. For example, Deprag’s turbine 6 HP cup stone grinder weighs in at 8.8 lbs, some of its 4.1 hp competitors vane motors weigh in over 14 lbs!

Click Here to learn more about Deprag's Turbine Grinders.

Electric Grinders offer a unique benefit of maintain their rpm underload but often are not seen as a durable factory tool. Suhner flexible shaft grinders have been trusted industrial solutions for decades. Suspending the motor independent from the hand piece, these machines offer unmatched power to weight ratio compared to any electric tool on the market and rivals the weight on an air tool but these tools are so powerful, even the burliest foundryman has trouble trying to slow down these work horses.

Contact us today to learn more about Suhner Flex Shaft Grinder and schedule your on-site demo!

AEHH has been heavily involved with the pioneering of diamond wheels for the foundry industry. Over the past 10 years, diamond coated abrasives have proven beneficial in gray and ductile foundry applications. AEHH has now paired high quality diamond wheels with high speed grinders from Deprag and Top Cat. These high-speed tools allow the wheel to run more freely, resulting in extended wheel life.

Contact us today to learn more about diamond wheel solutions or schedule an onsite demonstration.